Reliable Machine Tool Audit & Retrofit Solutions

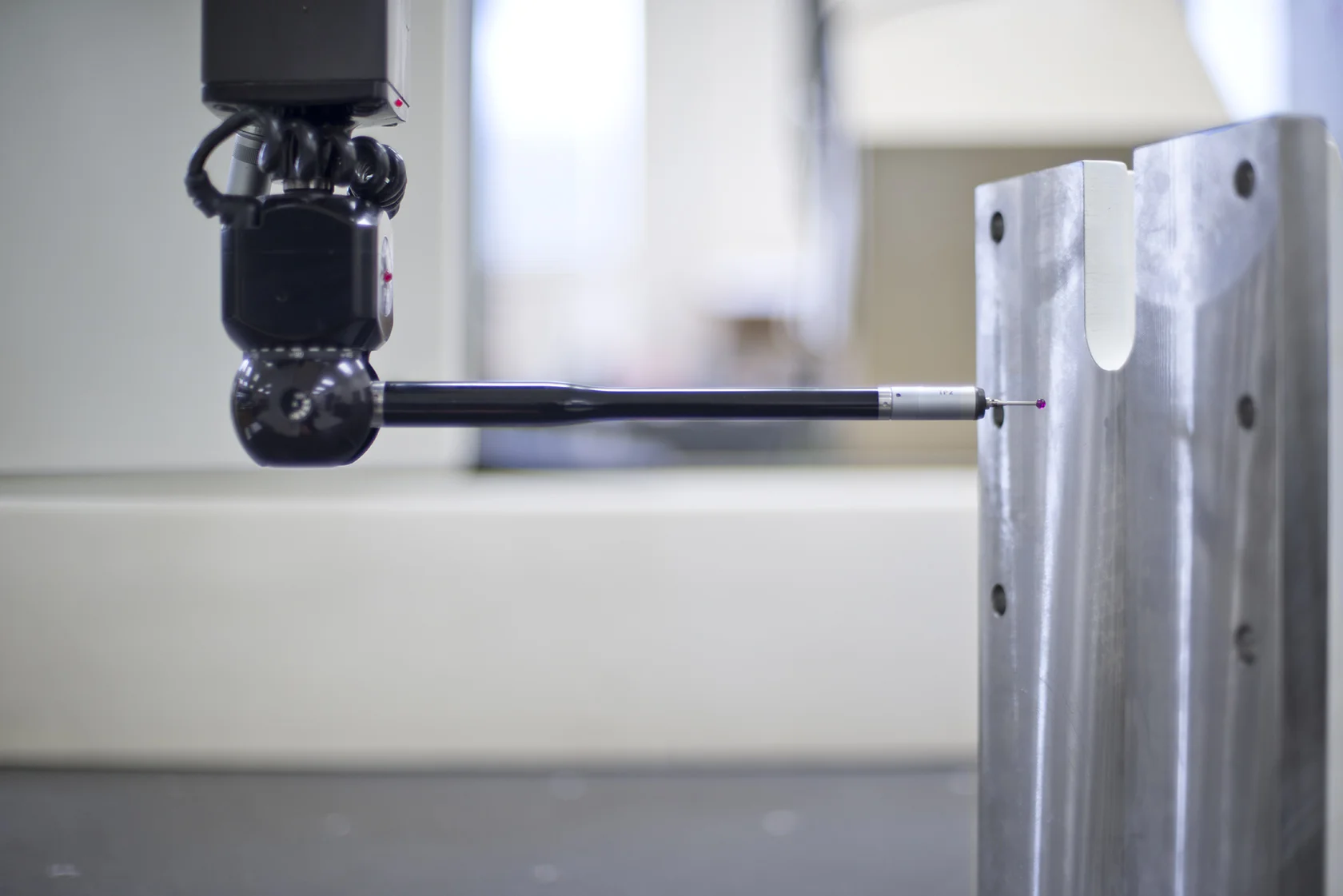

Colonial Tool's updated Inspection room has many start of the art advanced equipment to ensure high quality Spindles, Fixtures, Broaches, Advanced Cutting Tool Systems, and Machines leaving the facility made to precision specification. Colonial Tests all products before shipping and their experience in this practice is what makes them a reliable manufacturer. Colonial Tool stands by their products and is an industry leader with over 80 years of involvement in production.

Colonial Tool's Inspection department consistently performs proper Analysis, Audits & Tests using advanced cutting edge equipment and technology.

Machine Audit

Colonial has been involved in machine tool audit and retrofit solutions, for transfer lines and high output manufacturing. We can help you get more productivity out of your current machine, by providing you with a custom retrofit that will save you both time and money.

Our machine audit team will assess your process/application, and will propose improvements in key areas of your machine.

Here are some features and benefits:

Minimize maintenance costs through decreased downtime

Maximize revenue through increased up-time

Decrease your cost-per-piece

Mechanical Stability Test

There has always been an effort—among most machine tool manufacturers—to enable various design features, in order to produce stable machine tools; this is done by means of minimizing friction, vibration and thermal effects.

Achieving machine tool stability is a complex process, which requires involvement of all participating parties—from vendors to end users.

The machine tool manufacturer plays the most important role, as the creator and integrator of the machine. It benefits our case to list potential causes of instability and integrity of machine tools:

design defects

manufacturing defects

improper machine foundations

operational stresses

maintenance actions

aging

As we can see, not all causes lie with the machine builder.

While all good intentions are there, one cannot predict the exact timing and magnitude of future instability issues; this is due to production parameters, environmental conditions, operational errors, etc.

Here at Colonial we are renowned for our "RAS" (Rigidity-At-Speed) precision spindles.

We are following the same philosophy when it comes to machine tools as a whole. We offer our services for mechanical stability testing.

Complete written reports along with proposed corrective actions are created and handed to our customers. More than that, while we are at it, we can apply the corrective action.

Give us a try, if you haven't done so already. Our sales staff will be more than happy to assist you.

Vibration Analysis

With time due to production and assembling tolerances, normal wear and load dynamics the moving parts of a machine will develop vibrations that will eventually lead to breakdowns.

Vibration levels do not raise or become excessive for no reason, something causes it: unbalance, misalignment, worn gears or bearings, looseness, the list goes on.

The initial step is to identify the problem to understand what caused it from its apparent symptoms.

To interpret the data, we need to observe, measure, and then analyze.

It is considered a good practice to eliminate options that are not supported by available data, and to focus on the ones that are consistently converging.

While analyzing and concluding on the data extracted is a relative short task, it is of nevertheless important since it will become the starting point of a laborious process.

This will involve a lot of man hours and other resources, in order to complete the remedial work.

Our team, of highly trained and certified vibration technicians, has over 100 years of combined experience in the field.

Your machine will be in good hands, while you will experience a courteous and friendly service.

Do not hesitate to call us with all your vibration challenges.