Your Industry Leader in Machine Spindle Rebuilds

Colonial Tool has always maintained its leadership over our competition for Machine Spindle Rebuilds by constantly updating our procedures, equipment, but more importantly our people. No matter what the spindle rebuild is, Colonial has a laid out step by step process to deal with it. And these procedures are the same with re-building the spindle, bench testing, and final inspection. We have the latest equipment to deal with ever changing CNC cartridge motorized spindles from every manufacturer in the world (see below). We have dedicated Spindle Engineering staff on hand, not only to come up with innovated new Spindle designs for a constantly changing market, but also are very hands on with Spindle Rebuilds as well. Several times, our Spindle Engineers have actually improved our competition’s existing designs to increase the working life of our rebuilds substantiality, and we are capable to reverse Engineer your spindles, to produce a new spindle spare if you required. Next our Assemblers are highly motivated people, with years of spindle experience. Our Assemblers have gone overseas for training several times on state of the art cartridge motorized CNC Precision spindles, and the Assembler that pre-tests your rebuild spindle, then dis-assembles your spindle is the same person that re-builds, tests, and inspects your rebuild spindle…. A to Z policy.

Here are some of our Spindle Rebuild satisfied customers are Ford, GM, Chrysler, CAT, Cummins, MAG, Comau, Ingersoll Production Equipment, Linamar, Red Viking, Raven Engineering, Cell Con, Large and small machine house, and die shops

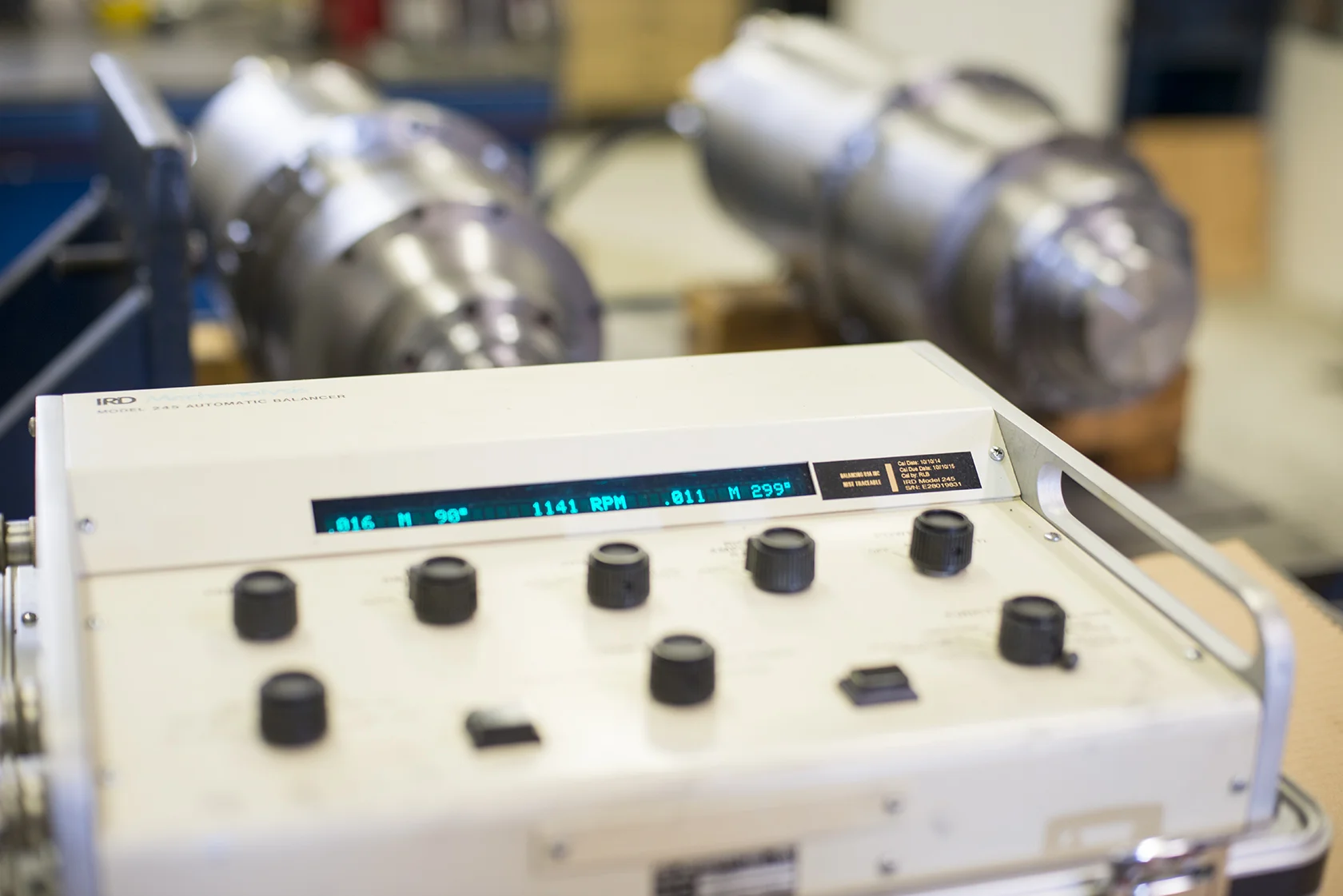

Spindle Rebuild Equipment

1. Colonial has in the last two years included two major drives to ensure that we can run any servo motorized spindles. First is a closed loop feedback drive for any servo motors with encoders, and second is a large drive to also run servo motors, and permanent magnet motors

2. Colonial has also purchased a D.C.M.U. (Digital Calibration and Measurement Unit) purely to “set the flag” for encoders, which is far superior method than the common “black box” method.

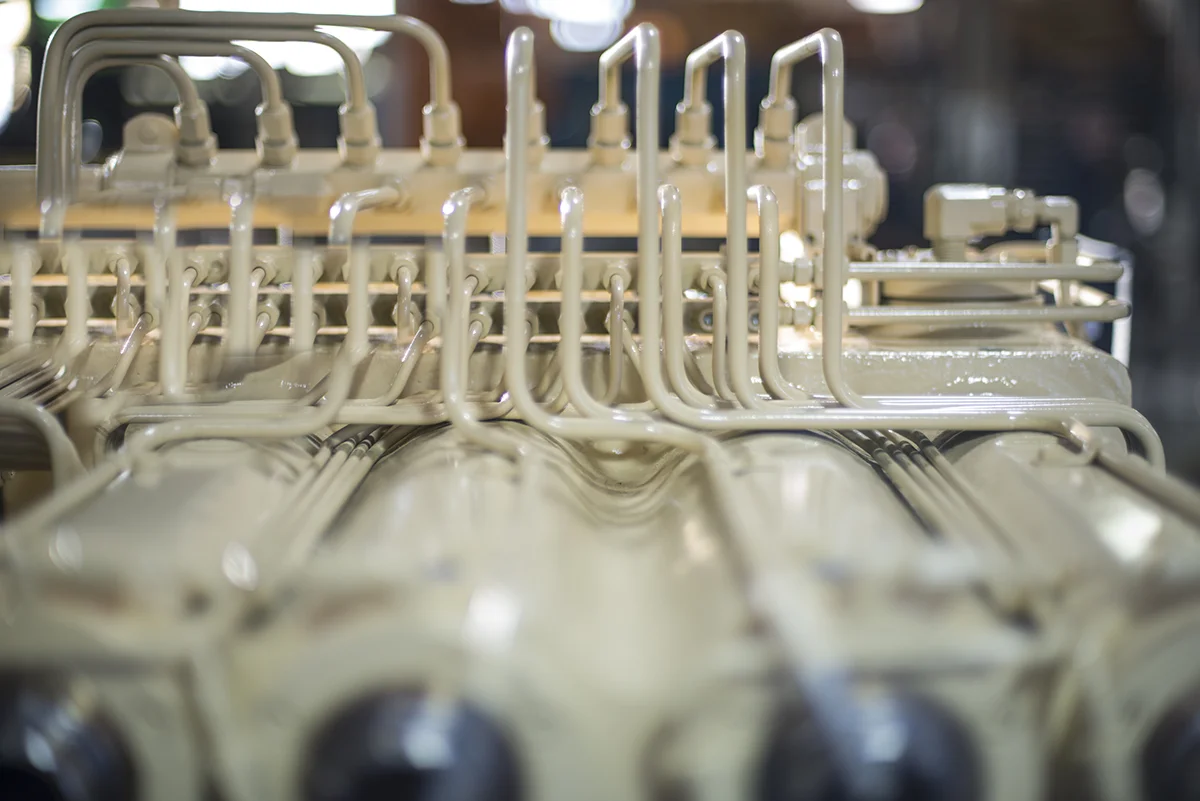

3. We have high pressure lubrication system as well as several standard “air over oil” pump lubrication systems.

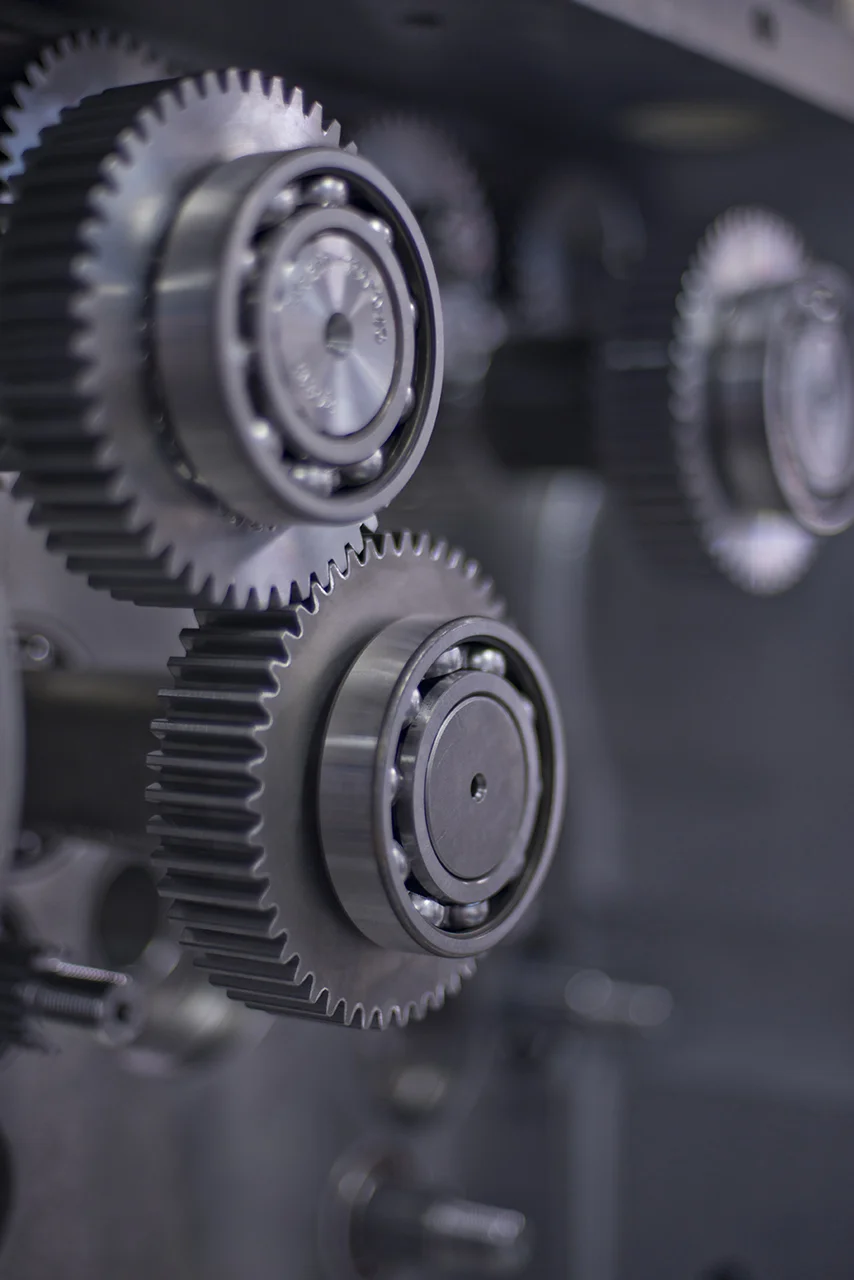

4. We have all the correct gauging equipment to accurately set the tapered bore roller bearings, which gives us accuracy down to .00005” clearance, if required. We have all gauges to cover 12 different sizes of tapered bore roller bearings.

5. Two different mobile high pressure hydraulic systems

6. DEA 1203 CMM for checking off set dimensions, if necessary

7. We are ISO Certified, so all gauging equipment, is calibrated on a regular basis

8. IRD dynamic two plane balancing machine, with IRD 245 automatic digital pack for precise live balancing of your spindle shafts and motor rotors.

9. IRD 1250 dataPac for pre and final Vibration analysis of your rebuild spindle

Spindle Rebuild Procedures

1. Every spindle is pre-tested (prior to dis-assembly) for Vibration Analysis, drawbar pull force, encoder readings, tooling mount run outs, axial compliance, motor condition, cooling jackets, air purge flow, etc., so we know exactly what the rebuild Spindle’s issues are prior to dis-assembly.

2. The spindle will then be dis-assemble (with pictures taken at every step), then a detailed report is provided which explains what is necessary to restore proper fits and sizes.

3. Purchasing will then look for the best price available for purchased items such as bearings (maintaining proper preload and contact angle), and seals.

4. Customer will then be notified of exact best cost to rebuild their spindle, and will need to give their approval prior to the rebuild.

5. Pending Customers approval, most repairs are completed in two to three weeks.

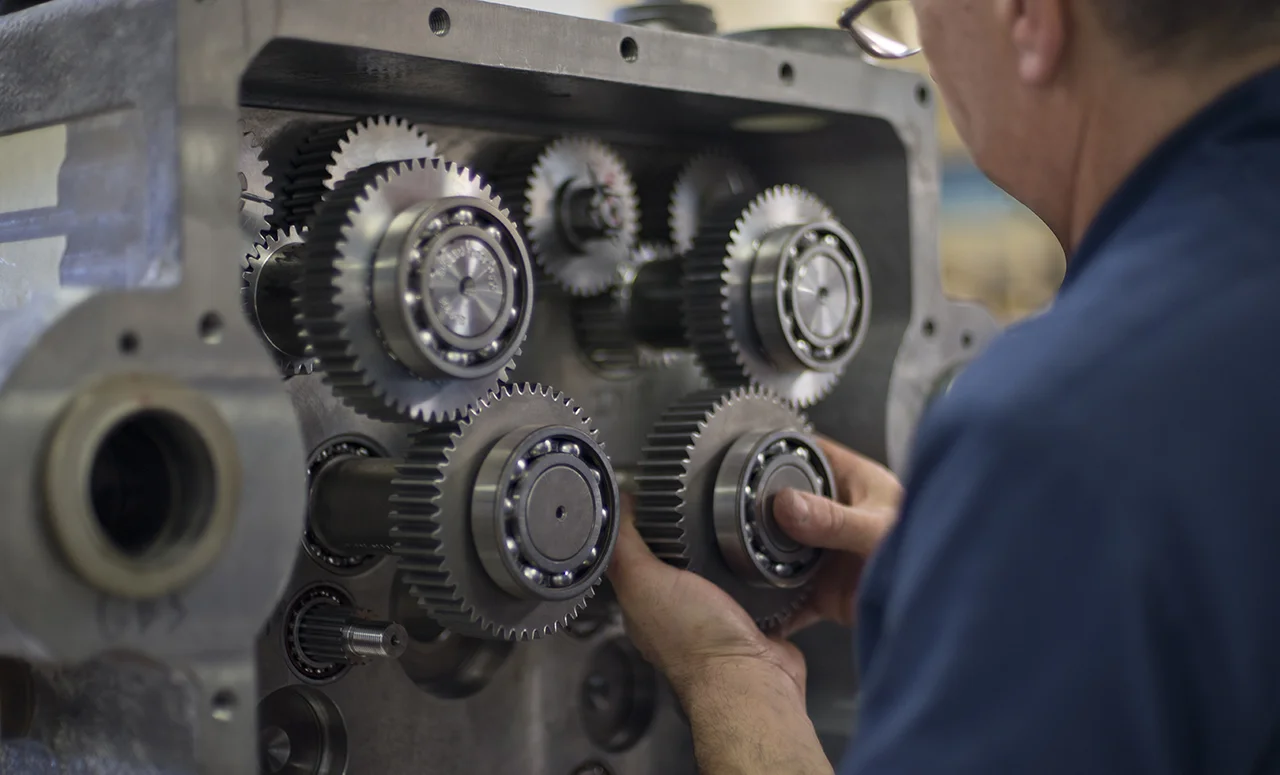

Our Spindle Rebuild Team

Our Assemblers were hand chosen for this job, and usually have a back ground in Machine Building. Each Assembler has year’s experience in Precision Spindles, which including building brand New Spindles, as well as and Rebuilding your existing Spindles. The law here is whomever starts on a Rebuild Spindle job, is the person that finishes the same Rebuild job…….no exceptions. All Assemblers are well versed in using all the specialty equipment listed above, and are responsible for their own tools as well.

Because we manufacture New Precision Spindles to our Customers special requests and specs, we have a full staff of Spindle Engineers in house. They are versed in Solid Works, or Auto Cad, which ever the end user prefers, BUT they are also called into the Rebuilds of your Precision Spindles, looking for design improvement when we know that this particular Spindle Design could be improved. Also have full Spindle Engineering in house, allows us to Reverse Engineer your specific spindle, at your request, and can then provide you with a NEW duplicate spare spindle to match your Rebuild Spindle. Very few Spindle Rebuild houses would have an actual Spindle Engineer, unless they produced new spindles as well. Our Spindle Engineers are a very important tool, when it comes to Spindle Rebuilding.