High-Quality Precision Broaching Tools

Colonial Tool manufacturers the highest quality precision broaching tools and will service your tools regardless of original manufacturer. Our 24 hour total solution house will have your new broaching tools ready for production even with inflexible deadlines. Send your broaching tools to Colonial for fast and reliable broach sharpening!

When you trust Colonial Tool with your broaching tools, you get years of experience in the manufacture and repair of all types of tools. We can build, repair and re-manufacture any broaching tool, including:

Broaching Tools - Designed, Manufactured & Delivered!

Round w/Flats

Elongation

Square

Rectangle

Polygon/ Hex

Involute

Serration

Straight Side

Bearing Cage

Cam form

Fur Tree & Dove Tail

Flat Form

Slab Form

Carbide Insert/ Shells

Wrench & Pliers

Special Keyway

Steering & Rack

Punch

Blind Hold/ Spline

Turbine

Pot Ring Sets

Pot Stick Sets

Spiral Gullet

Rifling & Gun

Chain & Continuous

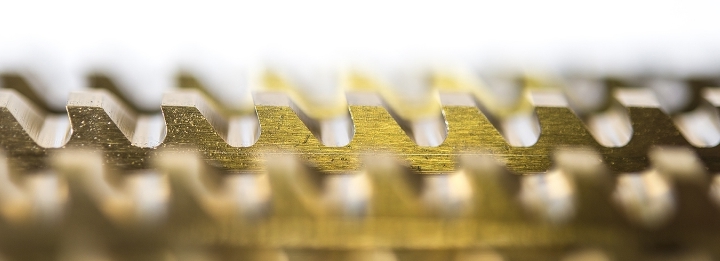

Spline Broaches

One of the most common broaching operations is, cutting splines or serrations in machined holes.The broaching tool is guided in the round hole, the top of each broach tooth cuts the splines progressively deeper, generating the sides of the form as the depth increases. Splines, either straight or involute and serrations, are produced efficiently by broaching.

From standard involutes to special splines, Colonial is the supplier you want to help you achieve the lowest cost per piece. With our in-house engineering, let us design the best broaching tool to suite your application. We can do standard-design broaches from our catalog as well as custom broaches that meet your specifications and requirements.

Choosing a leading broaching machine manufacturer like Colonial Tool allows you to extract more from your equipment and tooling. Don’t settle for standard, off-the-shelf broaching tooling when custom tooling can save you time, effort and money.

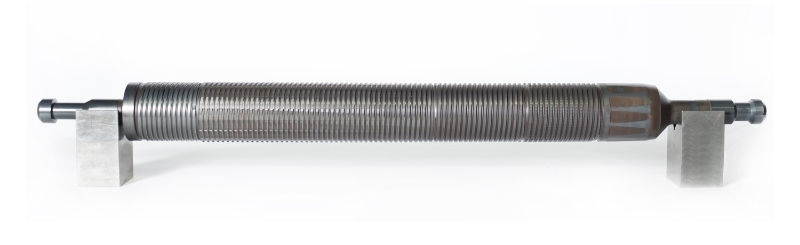

Round Broaches

Manufactured using Colonial's own U.S. patent # 4850253

Round precision I.D. pinion gear broaches

Can maintain hole-size tolerances of +/- .005mm with a .4 micrometer finish

Our manufacturing methods can also be applied easily to other applications.

All broaching tools are C.N.C manufactured in our facility.

Heat treating of all broaching tools is also completed in house for complete control over the manufacturing process.

Round broach capabilities, from 6mm diameter up to 300mm diameter X 2600mm, in overall length.

Prototype testing of broaching tools and applications are available.

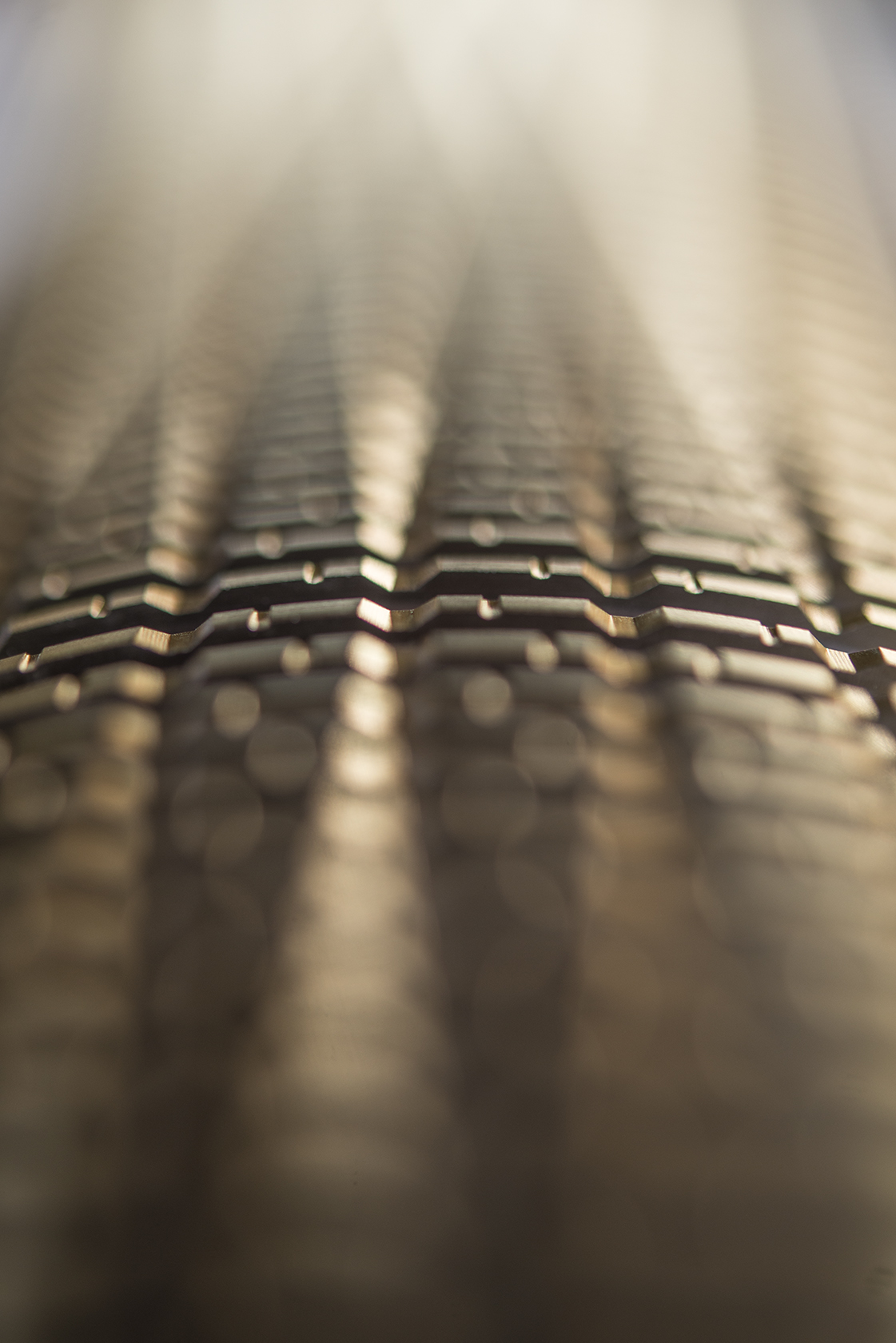

Helical Broaches

Broaching is the most economical method for cutting spiral transmission gears and similar parts.

The helical cutting teeth are formed to the desired customer's specifications and helix angle. Colonial’s option of spiral gullet teeth, results in superior part finish by creating less vibration and in turn longer broaching tool life.

Colonial Tool Group is a global leader in manufacturing of all types of broaching tools.

We have been able control our costs and quality by exercising complete control over the design and build of all our products, including in-house heat treatment and surface treatments. We pride ourselves on the services we provide, relationships we build with our customer base, and our world-class products.

For all products manufactured, we help our customers achieve the lowest cost per piece, by educating you on the best practices for your broaching tools by providing in-field service staff, technical resources to assist in trouble shooting, and consultation on part processing, machine evaluation, handling.

Colonial has the capacity to manufacture broaching tools as small as 6mm in diameter to as large as 300mm; our maximum length capacity is 3000mm”. Our Standard broaching tool deliveries are 8-10 weeks from receipt of order, but we also offer premium deliveries of 2-4 weeks if required.

We choose quality materials, bearings and other parts to ensure the highest quality and durability possible for your broaching tools. Our CNC machining centers give us high precision when cutting or sharpening your tools for maximum accuracy. The result is a broaching tool that can meet even your tightest tolerances and give you more hours of reliable service. This allows for:

Less downtime.

Less scrap.

Less set-up time.

Choose broaching tools from Colonial Tool and give your business or tool shop a real advantage. When you equip yourself with the top tools from a leading broach manufacturer, you’re saving time and money in the long run. Sub-standard broaching tools that require frequent adjustment or repair add a lot of downtime to your operations and significantly affect your throughput. Opt for the broaching tools from Colonial Tool that deliver leading performance and precision.

Steps to Broach Tool Repair

If your existing lot of broaching tools are showing wear, we can take care of their repair. There are two types of maintenance we can perform on broaching tools:

Planned maintenance on tools as they are starting to wear and drift from tolerance.

Repair maintenance on tools that have broken or are at risk of failing.

At Colonial Tool, we have years of experience rebuilding and repairing high-speed steel and carbide broaching tools so that you can get the maximum value out of your broaching tools investment. We have the tools, equipment and knowledge to repair any type of broach from any manufacturer.

Before we start repairing your broken broaching tools, we do a full analysis to determine the condition. We document the wear and issues with your broaches so we can compare them to the repaired result. To ensure consistent service when repairing your broaching tools, we apply the following systematic steps:

We start by inspecting and documenting your broaching tools (with measurements, photos and bench tests).

We create a detailed report describing the condition of your tools and the necessary repairs.

With your approval, we disassemble your tools and make the necessary repairs.

We machine and re-cut where possible and use quality replacement parts when new parts are needed.

Once reassembled, we re-test and re-measure your tool to document the repairs.

When you get your broaching tools back, they’re ready to put to use right away. Tool repair already takes time and can affect your schedule, so we work fast to get them back into your hands as quickly as possible. This is our way of adding value to our broaching tools repair services.